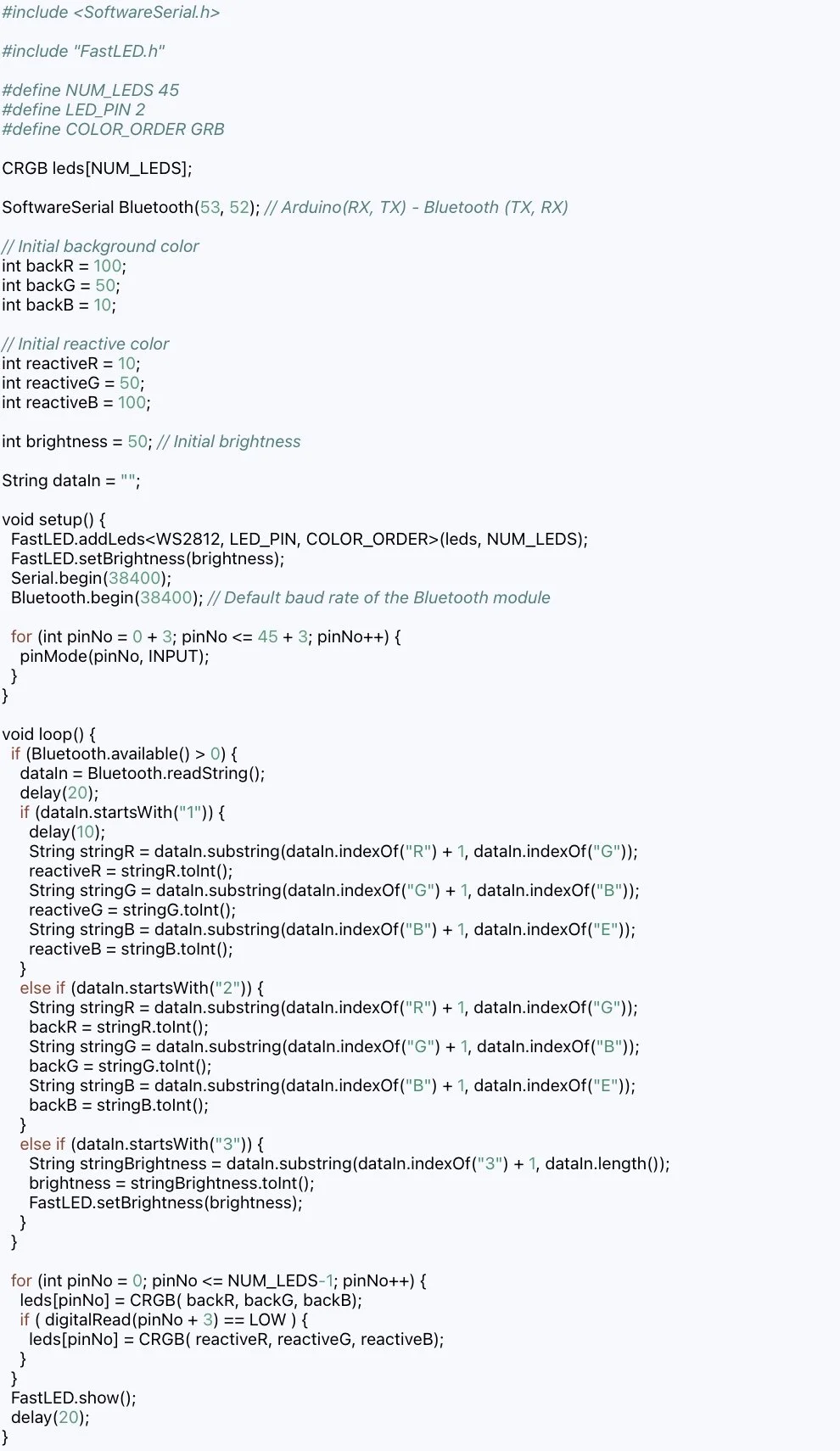

IR-Activated LED Interactive Table

Objective:

This was my first personal engineering project, created to apply what I had learned in high school and translate it into a real, functional build.

Solution:

Design and build an interactive LED table that uses infrared sensors to detect proximity and change the LED colors in response.

Tools/Skills Used:

Arduino IDE, Microelectronics, Addressable LEDs, Soldering, Woodworking, Manual Mill & Lathe

Approach:

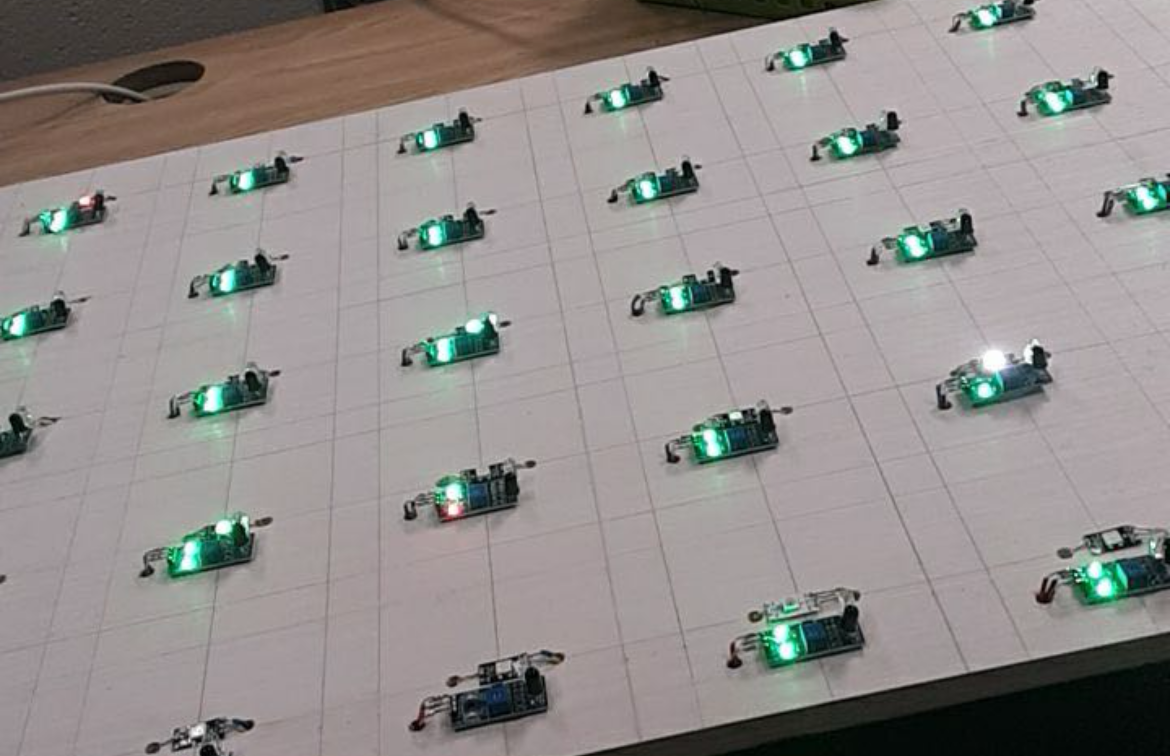

Built a table cavity to house the electronics, assembled a custom board containing 45 individually addressable LEDs paired with infrared proximity sensors, and programmed an Arduino Mega to control color changes based on detected movement.

My Role:

Designed the table and electronics layout, learned and performed the required soldering with guidance from my high school engineering teacher, and wired and integrated all components into the final assembly.

Results/Impact:

Created a fully functional, wall-powered interactive LED table that responds dynamically to user interaction — serving as the project that sparked my passion for hands-on engineering and building things from the ground up.

This was the first engineering project I ever built on my own, and I started it with the goal of turning what I had learned in high school into something real. I wanted to create something interactive, visual, and fun to use — something that would make the learning process exciting. The concept of an LED table that changed colors depending on what was placed on it felt like the perfect challenge. It was a project that combined electronics, coding, and fabrication all in one.

The goal was to design a table embedded with LEDs and infrared sensors that could detect when a hand or object was near and then respond with color changes. This meant integrating physical construction with circuit design, microcontroller programming, and sensor logic. For a first project, it was ambitious, but that was part of the appeal. I wanted to learn by doing something real, not just following a tutorial.

I designed a cavity inside the tabletop to house all of the electronics and wiring. I then laid out a custom board holding forty-five individually addressable LEDs paired with infrared proximity sensors. These were driven by an Arduino Mega board, which I programmed to read sensor inputs and output dynamic color patterns. The mechanical and electrical components needed to fit cleanly together, so I used woodworking tools and machining equipment to build a precise enclosure.

Because I was new to electronics at the time, I learned soldering, circuit routing, and signal wiring as I went. My high school engineering teacher helped show me the basics, but I completed the majority of the wiring and programming on my own. There were hundreds of individual connections to make, and every one needed to be solid for the table to function. This part of the build taught me attention to detail and patience.

The finished LED table not only functions as intended, but it also marks the moment I realized how much I enjoy engineering. It showed me how math, code, and physical materials come together to create something you can touch and interact with. The setback in the project taught me resilience, problem-solving, and how to stay calm when things go wrong. Looking back, this table is more than just a project; it’s the beginning of my identity as a hands-on engineer.

About three weeks before the project was supposed to be finished, I accidentally fried the entire circuit. I had purchased the wrong power conversion box — one meant to go directly from wall voltage to 5V DC — but it wasn’t regulated properly, and the surge destroyed the board. I had to desolder every LED and sensor, rebuild the entire board, and rewire the system from scratch in only a few weeks. That setback was frustrating, but pushing through it is one of the things I’m most proud of about this project.

Once the electronics were rebuilt, I reinstalled everything into the table and reprogrammed the Arduino. The sensors responded correctly, the LEDs animated smoothly, and the interaction felt intuitive. After weeks of troubleshooting, rebuilding, and refining, everything finally worked the way I imagined when I started. Turning the table on and watching it light up for the first time was incredibly rewarding.