Spherical Bearing Housing Torque Fixture

Objective:

For over 20 years, associates have lacked a reliable method for installing rod ends onto actuators, resulting in difficult, inconsistent, and occasionally unsafe assembly practices.

Solution:

Design a dedicated fixture that protects the bearing during installation while allowing associates to apply additional torque safely and consistently.

Tools/Skills Used:

Manual Lathe & Mill, Threaded Insert & Rod-End Assembly, Autodesk Inventor, GD&T, Operator Feedback & Prototyping

Approach:

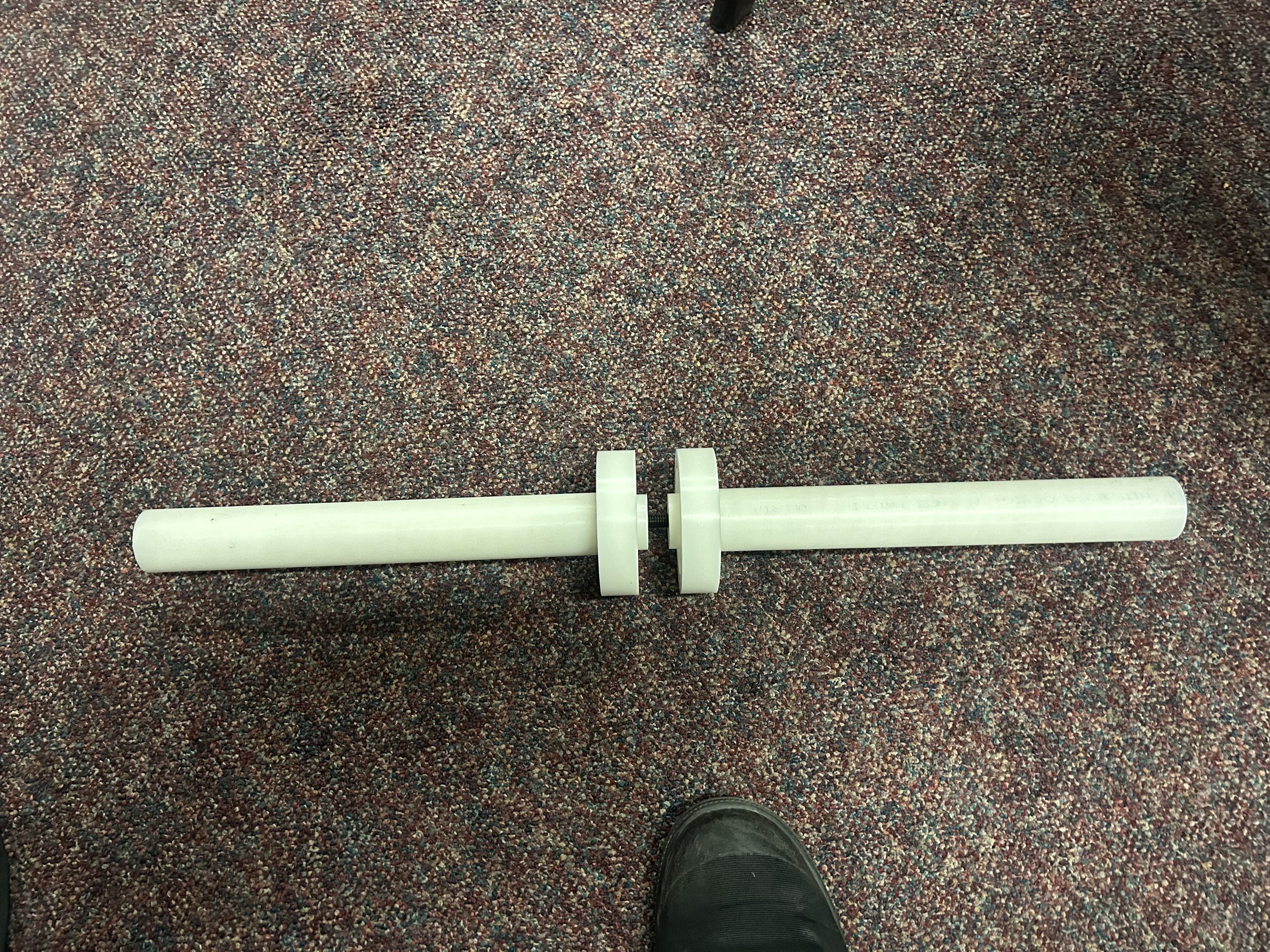

Measured and modeled all seven actuator types manufactured in-house, designed a fixture that passes through the bearing without loading it while seating against the surrounding housing, and began machining torque-assisting rod adapters to standardize installation.

My Role:

Worked directly with associates to understand their workflow and pain points, then designed, prototyped, and fabricated the tooling myself to ensure it matched real operational needs.

Results/Impact:

The fixture is currently being prototyped and tested. Once finalized, it will provide a safer, repeatable process for installing rod ends, reduce risk of part damage, and significantly improve assembly efficiency.

For over two decades, associates had been installing rod ends on actuators without a standardized or proper tool. This made the process difficult, inconsistent, and in some cases physically straining. The lack of control during installation also introduced the risk of damaging the bearing inside the actuator. It became clear that a dedicated tool was needed to make the process safer, more repeatable, and more ergonomic for the associates who perform this task every day.

The goal of the project was to design a fixture that would allow associates to apply the necessary torque to the rod end without transmitting any load through the bearing. The solution needed to be intuitive, durable, and compatible across multiple actuator models. Additionally, the fixture had to ensure the bearing remained completely protected throughout installation. Achieving this required both mechanical understanding and awareness of how operators actually interact with the parts.

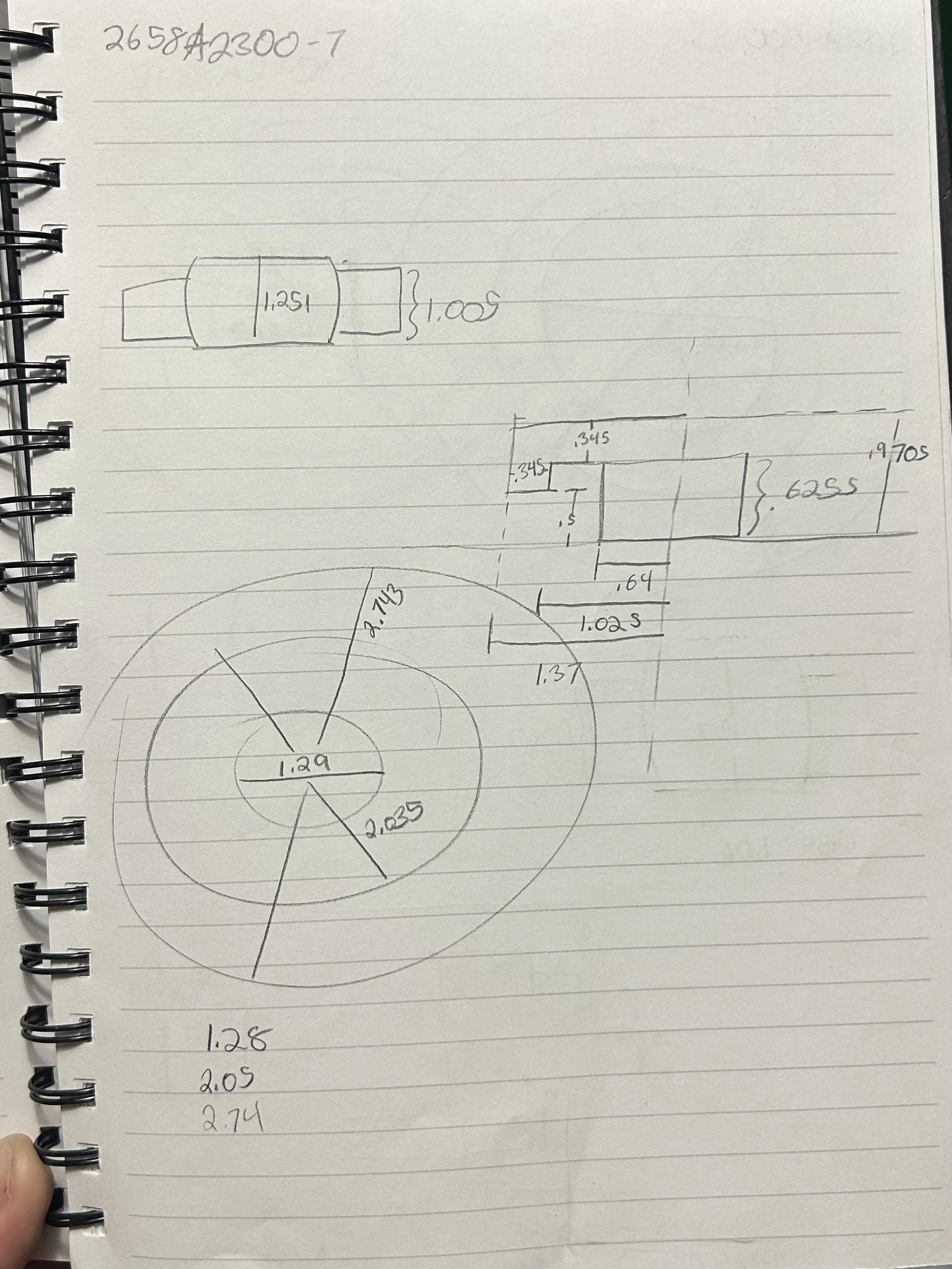

To begin, I gathered all seven actuator types that are produced in-house and compared their geometries, bearing sizes, and rod-end designs. I observed associates performing installations to understand the struggles firsthand — where grip was lost, where alignment shifted, and where torque application became difficult. These observations guided the core design requirement: the fixture must locate around the bearing while passing through its center, transferring force only to the surrounding housing. This ensured the bearing remained untouched and undamaged.

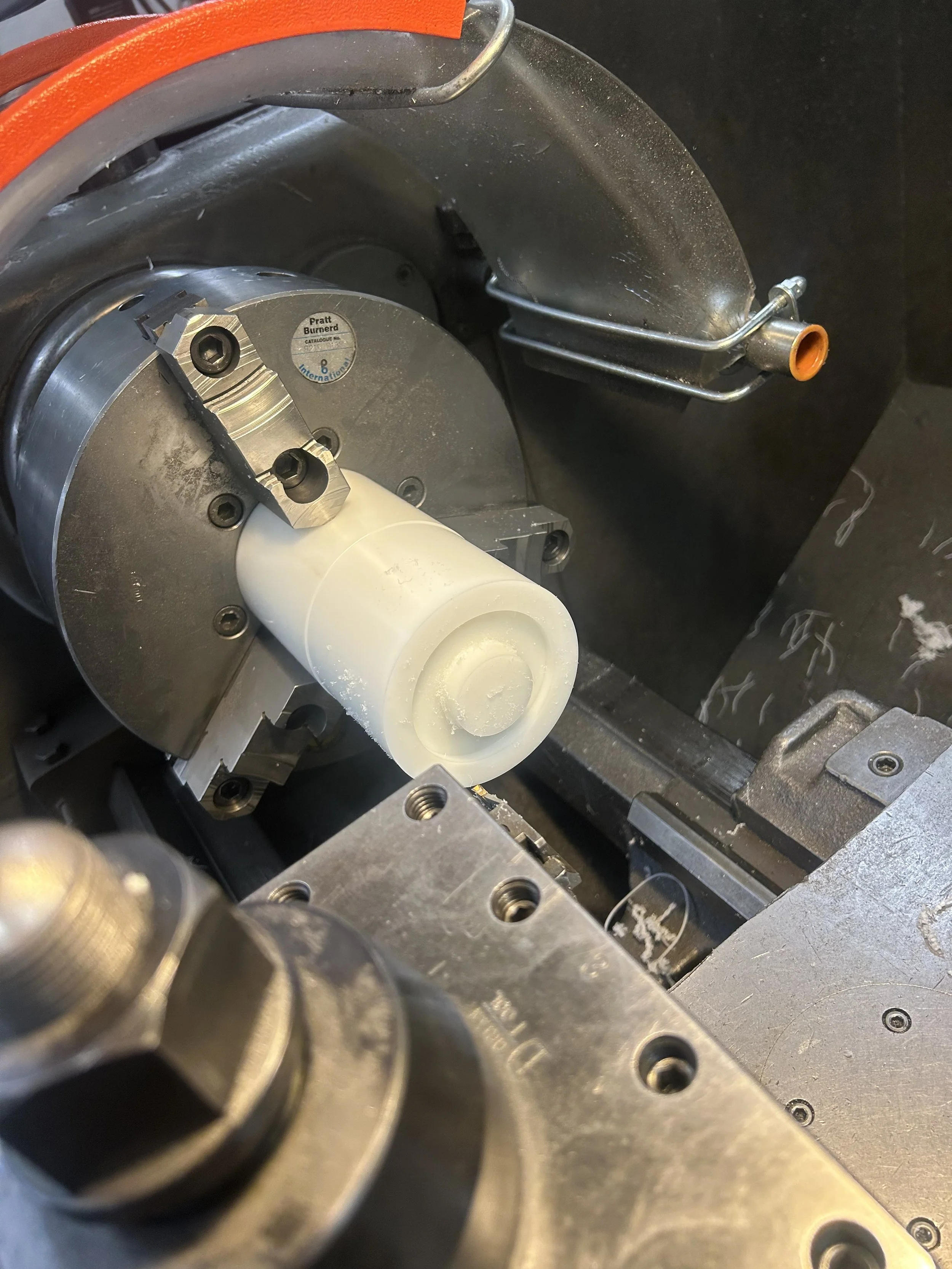

Using Autodesk Inventor and applying GD&T principles, I modeled a fixture that interfaces precisely with the actuator housing. The design includes a through-feature that avoids contacting the bearing and flat engagement faces that allow torque to be applied evenly. The backside geometry of the fixture was designed to mate with specialized torque rods, enabling leverage without requiring excessive operator effort. This approach balanced functionality, manufacturability, and operator usability.

The fixture is currently being tested and adjusted as final refinements are made. Once complete, it will provide a safe, consistent, and ergonomic method for installing rod ends across all actuator models. It is expected to reduce part damage risk, eliminate unnecessary physical strain on associates, and standardize a process that has historically varied widely between operators. This project represents not only a tooling improvement, but also a meaningful investment in the daily experience of the people doing the work.

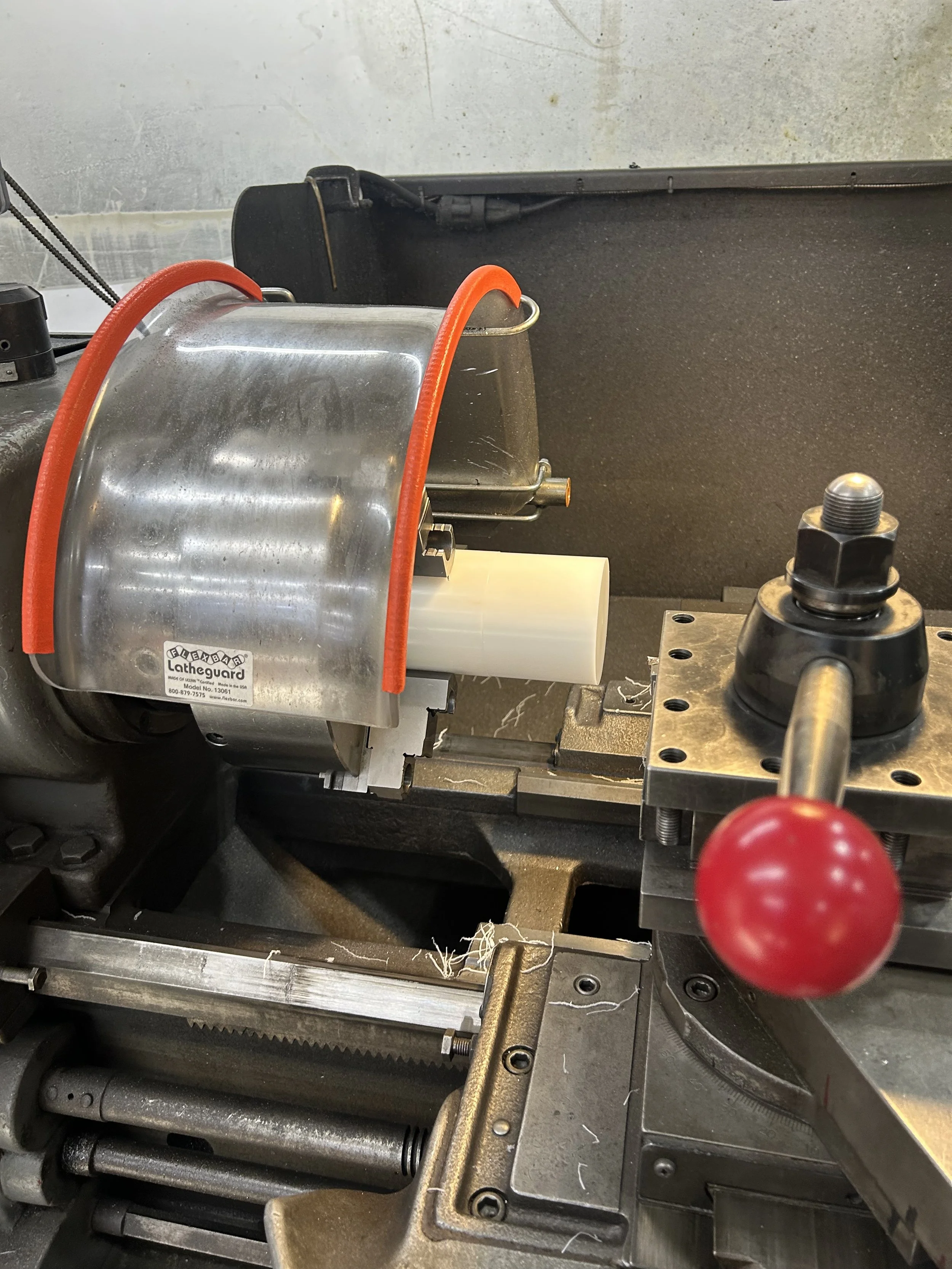

I fabricated the first round of prototype tools using the manual mill and lathe, machining the engagement surfaces and torque adapters to the required tolerances. Threaded inserts and reinforcement features were added where repeated load cycles were expected. Throughout machining, I consistently checked that the tool seated correctly on each actuator model. This prototyping phase focused on ensuring the tool was strong, comfortable to use, and aligned properly under load.

Throughout the project, I worked directly with the associates who would use the tool. Their feedback was invaluable — from handle shaping and angle positioning to the amount of clearance they needed for gloves and workspace constraints. This collaboration helped refine not just the mechanical function of the tool, but also the ergonomics and usability, ensuring it fit into their workflow rather than forcing them to adjust to a new one. These conversations shaped the fixture into something that would succeed in real daily use.