Thermal Spark Arrestor

Objective:

A new sandblaster was introduced to the shop that generated a significant amount of sparks, but there was no safe method to contain or direct them.

Solution:

Design and implement a fixture capable of capturing and dispersing sparks to prevent fire hazards and protect the workspace.

Tools/Skills Used:

Autodesk Inventor, 3D Printing (PETG & TPU), Spark Arrestor Design

Approach:

Designed a bell-shaped nozzle optimized for maximum spark capture within the confined workspace, 3D printed the body in PETG for rigidity, added a TPU sealing interface, and integrated a metal spark arrestor within the fixture.

My Role:

Measured available space, calculated the geometry required to achieve effective spark capture, modeled the assembly in Inventor, and fabricated and installed the final nozzle onto the sandblaster.

Results/Impact:

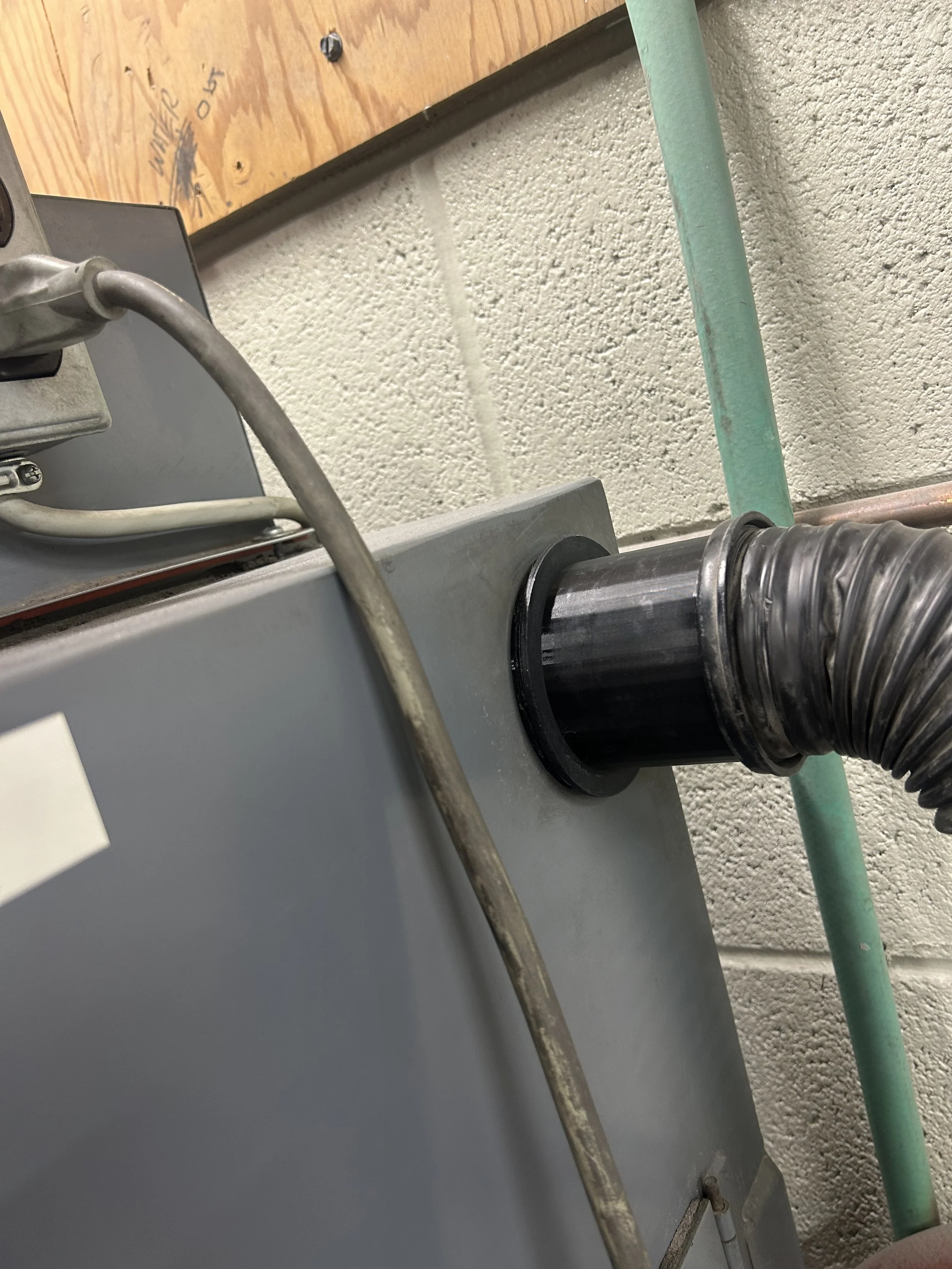

The final fixture safely contains sparks during sandblasting operations, significantly reducing fire risk and enabling safe, consistent use of the equipment in the workplace.

After a new sandblaster was introduced into the shop, it became clear that it produced a significant amount of sparks during use. The sparks were not being contained, creating a clear safety hazard and increasing the risk of accidental ignition near flammable materials. Because the sandblaster was required for daily work, the issue could not be ignored or postponed. A practical and reliable spark-capture solution was needed to keep operations safe.

The goal was to design a fixture that could attach to the sandblaster and effectively contain and disperse sparks without interfering with its normal function. The solution needed to be durable, easy to install, and compatible with the space constraints of the work environment. It also had to prevent sparks from escaping in unpredictable directions. Safety and functionality were the primary priorities.

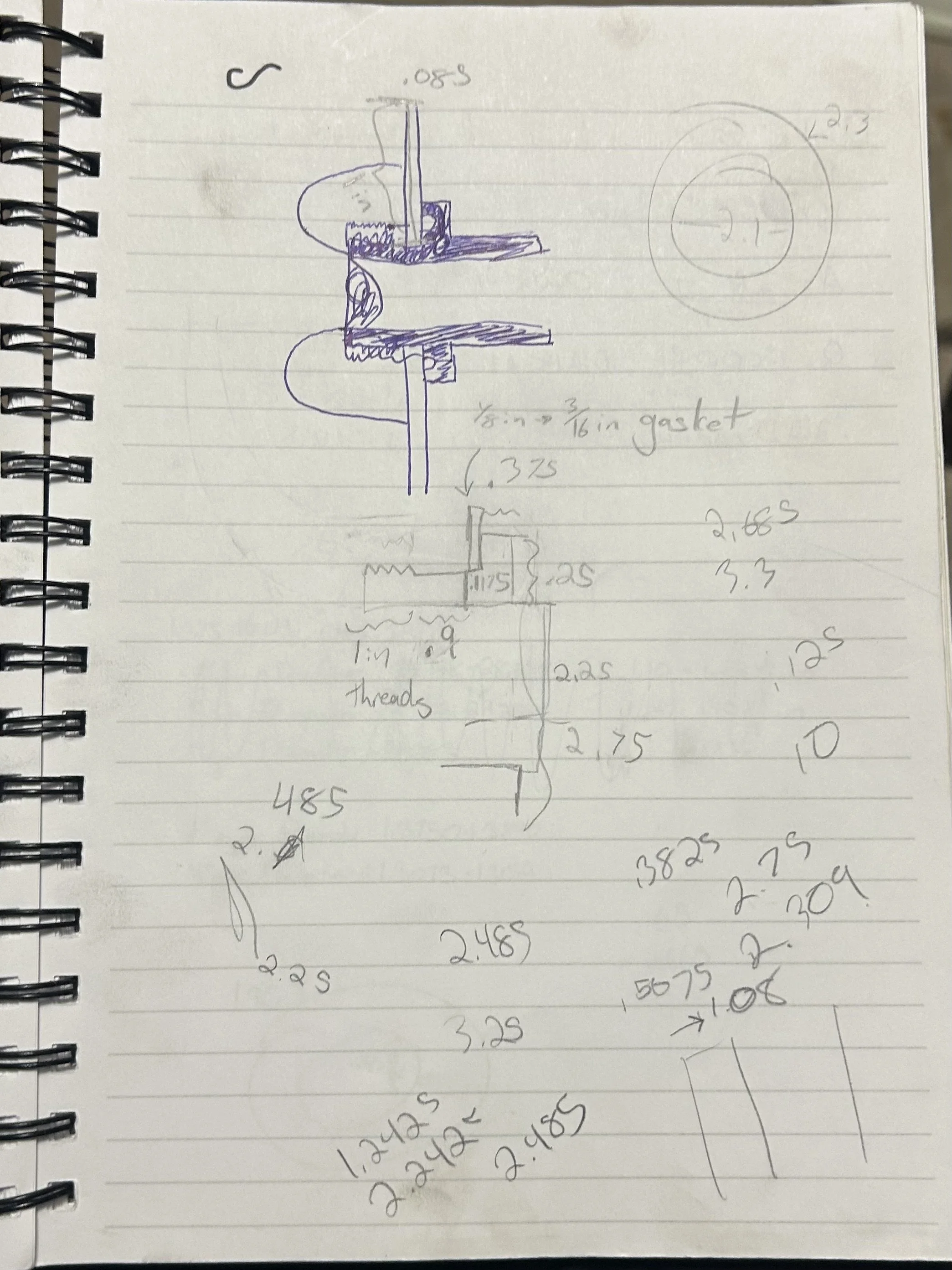

To begin, I analyzed the physical space surrounding the sandblaster to determine the maximum nozzle size that could be used. This required measuring available clearance, airflow direction, and the angle of blast dispersion. I also reviewed material considerations, since the fixture would need to withstand heat and impact without degrading. Understanding these physical constraints shaped the design approach from the start.

Using Autodesk Inventor, I designed a bell-shaped nozzle optimized to capture the widest possible spread of sparks based on the available space. PETG was selected for the main structure due to its heat resistance and rigidity, while TPU was used to create a flexible sealing surface for a tight and vibration-resistant fit. A metal spark arrestor was integrated inside the nozzle to safely diffuse hot particles before they exited the fixture. The final design balanced capture efficiency, durability, and manufacturability.

The completed fixture successfully contained and dispersed sparks during sandblasting operations, significantly reducing the risk of workplace fire hazards. It allowed the sandblaster to be used safely and consistently without needing to modify the machine or halt production. The solution improved safety, protected equipment and personnel, and cost far less than purchasing an external system. This project demonstrated how thoughtful design and resourceful fabrication can transform a high-risk process into a safe and reliable one.

Once the design was completed, I 3D printed the components in PETG and TPU and assembled the fixture for fit testing. The nozzle was installed on the sandblaster and checked for clearance, blast direction, and sealing. The integrated spark arrestor was securely fastened to prevent movement during operation. The fixture was then tested during normal sandblasting use to ensure it performed reliably.

Throughout the project, I communicated with operators to ensure the fixture was easy to use and did not interfere with their workflow. I also reviewed safety guidelines to confirm that the spark arrestor and nozzle design met workplace safety expectations. The iterative feedback from the team ensured that the final solution was both effective and user-friendly. This collaboration helped refine the design and ensured operator confidence in the new setup.